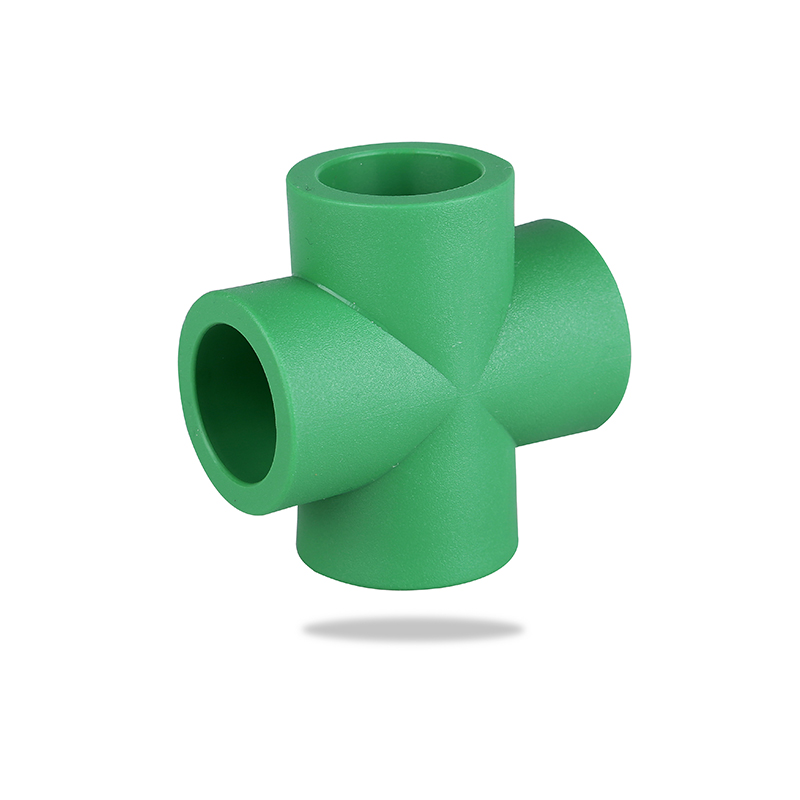

In low temperature environments, the hot melt connection of PPR pipes may be affected by the ambient temperature, resulting in increased construction difficulty or decreased connection quality. In order to ensure the reliability of hot melt connection of PPR Cross or other accessories, a series of measures need to be taken to cope with the challenges under low temperature conditions. The following are detailed solutions and precautions:

Understand the impact of low temperature on PPR hot melt connection

Material performance changes: PPR is a thermoplastic material that becomes harder and more brittle in low temperature environments. It requires higher temperatures and longer time to achieve the ideal melting state during hot melting.

Fast cooling speed: Low temperature environment will cause the melted PPR material to cool faster, which may affect the full fusion of the weld surface, thereby reducing the connection strength.

Construction operation difficulties: Cold weather may cause the construction workers' hand flexibility to decrease, increasing the risk of operational errors.

Preparation before construction

Choose suitable PPR materials:

Ensure that the PPR pipes and accessories used meet the requirements of low temperature environments, and select products with better low temperature resistance (such as reinforced PPR materials).

Check the specification consistency of pipes and accessories to avoid affecting the connection quality due to dimensional deviation.

Storage and preheating:

During transportation and storage, store PPR pipes and accessories in a warm environment to avoid long-term exposure to low temperatures.

Before construction, PPR pipes and accessories can be placed in a warm room or preheated with heating equipment (such as electric blankets) to make their temperature close to room temperature (recommended not less than 10℃).

Check tools and equipment:

Use a professional hot melt welding machine and ensure that its heating plate temperature is stable and meets the standard (usually 260℃±5℃).

In low temperature environments, the heating efficiency of hot melt machines may be affected, so it is necessary to test the equipment in advance to see if it works properly.

Precautions during construction

Increase the hot melt temperature

In low temperature environments, the heating plate temperature of the hot melt machine can be appropriately increased (but not more than 280℃) to compensate for the effect of ambient temperature on the melting effect.

Pay attention to controlling the heating time to ensure that the PPR material is fully melted, but avoid overheating and material degradation.

Extend heating and cooling time

Heating time: Adjust the heating time according to the ambient temperature, usually 10%-20% longer than the standard time.

Cooling time: In low temperature environment, although the cooling speed is fast, sufficient cooling time (usually 6-10 minutes) is still required to ensure that the weld surface is completely solidified.

Control welding pressure

During hot melt connection, the pressure applied should be moderate, avoiding too much or too little. Excessive pressure may cause the molten material to be squeezed out, while too little pressure will affect the density of the weld surface.

Avoid external interference

In low temperature environment, minimize the interference of external factors such as wind and snow on the welding process. A temporary insulation shed can be built at the construction site to keep the local temperature stable.

Other precautions

Construction personnel training: Ensure that construction personnel are familiar with hot melt connection technology in low temperature environment and operate strictly in accordance with the specifications.

Emergency plan: Under extreme low temperature conditions, if the quality of hot melt connection cannot be guaranteed, mechanical connection methods (such as compression joints) can be considered as a temporary alternative.

Through the above measures, the adverse effects of low temperature can be effectively overcome to ensure the sealing and durability of the connection.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português