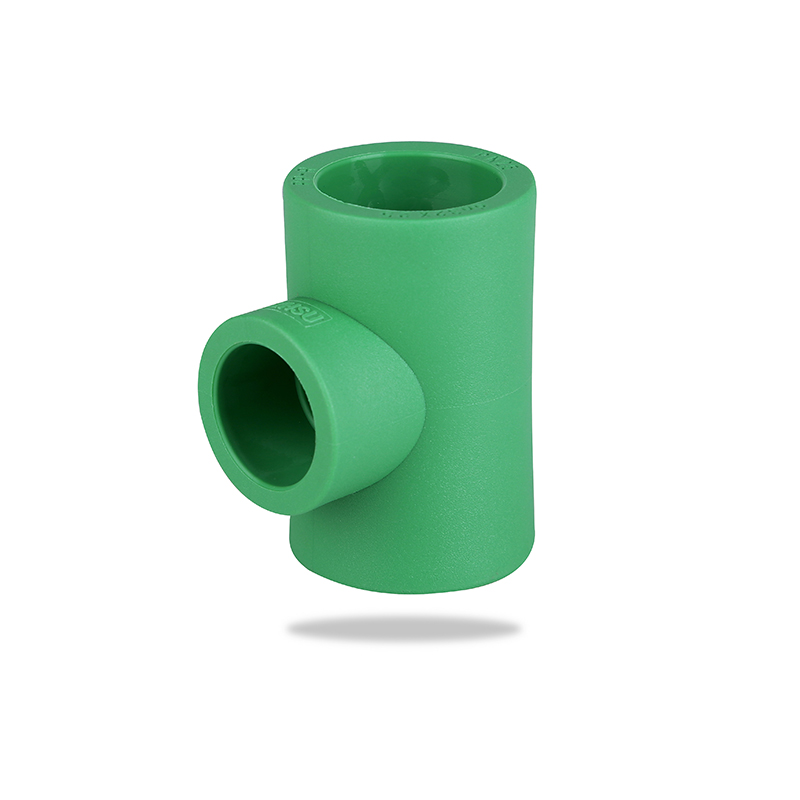

The design of PPR (Polypropylene Random Copolymer) reducing tees is engineered to accommodate different pipe diameters and flow requirements through several key design features and considerations:

Branch Size and Configuration:

PPR reducing tees typically feature a larger main inlet that matches the diameter of the main pipeline. The branch outlets, which are smaller in diameter, are designed to connect to pipes of reduced size. This configuration ensures smooth flow transitions while maintaining structural integrity.

Gradual or Sharp Transitions:

Depending on the application and fluid dynamics requirements, PPR reducing tees may have either gradual or sharp transitions from the main inlet to the branch outlets. Gradual transitions help reduce turbulence and pressure drops, which can be beneficial in systems requiring smooth fluid flow.

Flow Characteristics:

The internal geometry of PPR reducing tees is optimized to minimize flow disruptions and ensure efficient fluid distribution. This includes considerations such as angle of entry, curvature, and internal surface finish to promote laminar flow and minimize frictional losses.

Pressure Ratings and Stress Distribution:

The design of PPR reducing tees takes into account pressure ratings corresponding to different pipe sizes and operating conditions. Reinforcements or thicker sections may be incorporated near junction points to manage stress concentrations and ensure structural stability under pressure.

Modularity and Compatibility:

PPR reducing tees are designed to be modular and compatible with other PPR fittings and pipes. This allows for flexibility in system configuration and adaptation to varying flow requirements without compromising sealing integrity or performance.

Installation Flexibility:

PPR reducing tees are designed for ease of installation, typically featuring socket fusion or butt fusion joints that ensure leak-proof connections. This installation method allows for quick assembly and disassembly when required for maintenance or system modifications.

Material Properties:

The material properties of PPR, such as its resistance to corrosion, chemical inertness, and thermal stability, are integral to the design of reducing tees. These properties ensure long-term performance and reliability in diverse applications ranging from potable water systems to industrial piping.

By integrating these design principles, PPR reducing tees effectively adapt to different pipe diameters and flow requirements, providing a versatile solution for various plumbing and fluid transport applications. This adaptability helps optimize system performance while maintaining durability and operational efficiency.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français عربى

عربى Português

Português 日本語

日本語 italiano

italiano Nederlands

Nederlands Polskie

Polskie